About Dust Extractors For Small Workshops

How Dust Extractors For Small Workshops can Save You Time, Stress, and Money.

Table of Contents8 Simple Techniques For Dust Extractors For Small WorkshopsEverything about Dust Extractors For Small WorkshopsNot known Facts About Dust Extractors For Small WorkshopsDust Extractors For Small Workshops - An Overview

The challenges for foundry dirt collection systems rotate around crystalline silica dust, carbon monoxide, as well as warm, which are harmful combinations. These elements make meeting air high quality requirements challenging as well as demanding. Consequently, when choosing a dirt control system for a shop, the initial consideration is the ability of the system to stand up to harsh as well as dangerous workplace problems.

Finish, or thermal spray, uses warmed material to steels to coat their surface areas. Dust collection systems for this kind of operation have to be especially developed to fit the kind of finish being applied. The objective of the system is to manage and decrease overspray and dirt. The common thermal spray dirt control system utilizes air ducts to move air to the collection tool. dust extractors for small workshops.

It would seem likely to raise airflow as well as activity, this kind of service might be ineffective and waste energy. The design of the booth depends upon the pressure of the air entering the cell or booth. For many systems, it is necessary to have a small vacuum cleaner in the booth to avoid feasible favorable pressure.

About Dust Extractors For Small Workshops

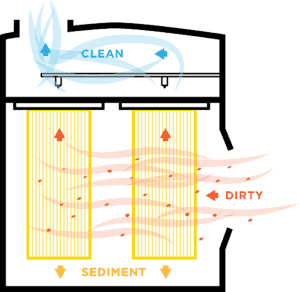

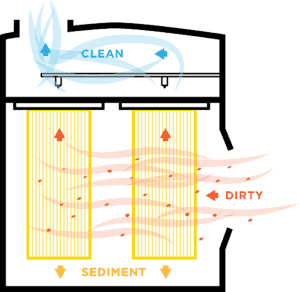

Another method is simply placing the makeup air connection on the top of the booth. No matter the style, it is essential for the cleaning of the air to have cross air flow. Just like a cleanroom, airflow in a thermal spray cubicle can be either straight or downward, though the down design is best for dust collection systems.

The pharmaceutical market is an extremely regulated sector with substantial as well as exact policies. Dust from drugs is created mainly during the manufacturing and also packaging of products. Each action of creating a drug, which consists of granulating, drying out, mixing, pressing, finish, as well as grinding, generates huge amounts of dirt that require to be removed.

Obstructing as well as controlling this circulation is the function of the dirt control system. When creating a dust control system for a pharmaceutical plant, the initial consideration is mapping the air flow system to track the path of dirt, fumes, existing air flow patterns, and feasible important source evolutionary adjustments. Given that lots of pharmaceutical dirts are combustible, the design of the ventilation system is extremely crucial.

HEPA filters are typically discovered in pharmaceutical dirt control systems considering that they are the most efficient as well as dependable. Just like a factory system, they are set up as an additional security to achieve no emissions. Reusing produces a wonderful offer of dirt as an all-natural outcome of lessening items to their basic materials.

Facts About Dust Extractors For Small Workshops Uncovered

Dirt stems after products are shredded, squashed, or have paint or lacquer removed. All reusing centers are required to abide by air quality criteria. As they work to fulfill high quality standards and control pollutants, they have actually recognized that dirt control is a major problem, leading to the wide use dirt collection systems to minimize and also have the trouble. dust extractors for small workshops.

When producers select a dust control system, they are recommended by producers about the kind of system that would certainly best fit their demands since buying and installing a dirt control system is a significant financial investment. Particulate matter can be found in a wide range of types, from silicon dust to wood chips and also sawdust.

The Best Guide To Dust Extractors For Small Workshops

Fabric filter bags in a cartridge system are the most reliable method for accumulating dust. Dirt his explanation collection systems are covered to include the dirt as well as tidy the air.

Plastic Dust High-Density Polyethylene (HDPE) dirt is created in the manufacturing of plastic panels when they are shaped and also formed on a side trimmer, mill, or miter saw. Paper Dust Among the more usual forms of dust is paper dirt, the side effect of the manufacturing of different types of paper.

With the intro of dust collection systems, employees are more secure and more protected. Sugar Sugar dirt is the by-product of the manufacturing of candy.

A baghouse system is the preferred system. Rice Dirt Rice dust has really fine and minute bits that gather during the production of rice-based items. A dirt collection system is needed for the protection as well as safety and security of workers. Silica Silica is among one of the most common materials on earth. It is a main component of several production procedures, such as the manufacturing of glass, ceramic tile, cement, as well as asphalt.